PRODUCT DETAILS

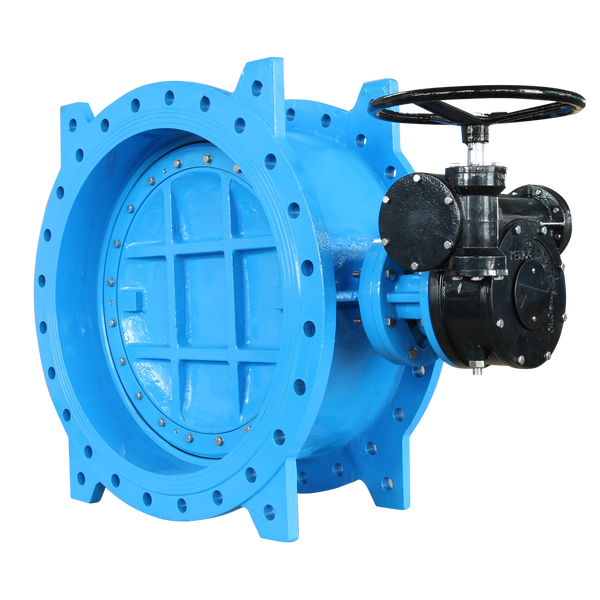

Double Eccentric Flanged Butterfly Valve Introduction

Double Eccentric Butterfly Valve is further improved on the basis of Single Eccentric Butterfly Valve. Its unique structural feature is that the axis of the valve stem not only deviates from the center of the butterfly plate, but also deviates from the center of the valve body. This double eccentric design allows the butterfly plate to quickly disengage from the valve seat when the valve opens, significantly reducing unnecessary excessive compression and friction between the butterfly plate and the valve seat. This improvement significantly reduces resistance to opening, reduces wear and significantly increases seat life. Due to the significant reduction in friction, the Double Eccentric Butterfly Valve can also be equipped with metal seats for enhanced performance and durability in high temperature applications.

Main features of double eccentric butterfly valve:

- Reasonable design, compact structure, easy to install and disassemble, easy maintenance.

- Eccentric structure reduces the friction of sealing ring and prolongs the service life of the valve.

- Completely sealed, zero leakage. Can be used in ultra-high vacuum conditions

- Replacement of the valve plate sealing ring, butterfly plate, shaft and other materials, can be applied to a variety of media and different temperatures.

The Double Eccentric Butterfly Valve is a marvel of engineering precision and a testament to advanced innovations in fluid dynamics. With its uniquely designed eccentric stem axis, the valve effortlessly breaks the mold, revolutionizing the way we control flow with functionality and breathtaking elegance. During operation, the disc disengages gracefully with minimal contact with the valve seat, which not only reduces wear and tear, but also ensures product longevity and reliability. This clever double eccentric configuration greatly reduces operating torque, ensuring smoother, more energy-efficient performance. In addition, the reduction in friction allows for the integration of a robust metal seat, thus extending the valve's field of application to high-temperature applications and providing peace of mind even in the most demanding environments. The Double Eccentric Butterfly Valve realizes the harmony of cutting-edge technology and durability, and is designed to not only meet but exceed the expectations of modern industrial needs.

Double Eccentric Flanged Butterfly Valve Drawing

Implementation Of Standards

| Category | Details |

|---|---|

| Type | Flange |

| Face to Face | API609, BS5155, DIN3202, ISO5752 |

| Flange | DIN, BS, UNI, ISO, ANSI, AS, JIS |

| Mounting Flange | ISO5211 |

| Working Pressure | PN16 (200PSI) |

| Application | HVAC, Water Supply&Sewage, Food&Beverage, Chemical/Petrochemical/Processing, Power and Utilities, Paper and Pulp, Ship Building |

Standard Materials Of Main Parts

| ITEM | PART NAME | MATERIAL |

|---|---|---|

| 1 | Bushing | BRONZE/EPDM |

| 2 | Bottom Shaft | SS420 |

| 3 | Body | GGG50 |

| 4 | Packing | EPDM |

| 5 | Retainer | CS EPOXY COATED |

| 6 | Taper Pin | SS416 |

| 7 | Disc | GGG50 |

| 8 | Disc Sealing | EPDM |

| 9 | Stuffing Flange | GGG50 |

| 10 | Support | CS |

| 11 | Top Shaft | SS420 |

| 12 | Cover | GGG50 |

| 13 | All Fasteners | A2-70 |

Dimensions:(mm)

REVIEWS

Download

FAQs

What is a butterfly valve? How do they work?

A butterfly valve is a common fluid control valve, mainly composed of a valve body, a valve seat, a valve stem, a valve plate, etc. The general operation uses a rotating valve disc to adjust the flow of the fluid. The valve disc mounted on the central axis rotates a quarter turn (90 degrees) to allow the fluid to pass (open position) or block the flow of the fluid (closed position). The intermediate position of the valve disc can allow precise adjustment of the flow.

What are the main types of butterfly valves?

The main types of butterfly valves are wafer butterfly valves, lug butterfly valves, flange butterfly valves, concentric (elastic valve seat), double eccentric (high performance) and triple eccentric (metal valve seat) butterfly valves.

In which industries are butterfly valves commonly used?

Due to the versatility and reliability of butterfly valves, butterfly valves are widely used in water treatment, chemical processing, oil and gas, HVAC (heating, ventilation and air conditioning), food and beverage, and pharmaceutical industries.

What materials are butterfly valves made of?

The valve body and valve disc of butterfly valves are usually made of stainless steel, ductile iron, carbon steel and other alloys. The valve stem is the part that connects the operating device and the valve disc, and is generally made of stainless steel. The valve seat and seal are usually made of elastic materials such as rubber, Teflon or other polymers, which play a sealing role to prevent the leakage of the medium. The selection of the sealing ring should be determined according to the nature of the medium and the working conditions to ensure the sealing effect and service life.

What are the benefits of using butterfly valves for the environment?

Butterfly valves promote environmental sustainability by achieving efficient fluid management, reducing energy consumption through minimal pressure drop, and safely handling environmentally sensitive fluids, thereby minimizing waste and optimizing resource utilization.

What are the advantages of using butterfly valves?

1. Simple structure, light and compact

2. Small flow resistance and large flow

3. Good tight sealing performance

4. Easy to operate and low torque

5. Suitable for a variety of media and operating temperature ranges

6. Economical and practical, easy to maintain

Why use butterfly valves instead of gate valves

Operation: Butterfly valves are quick to operate and can be opened or closed by simply rotating the handle 90 degrees, while gate valves require multiple rotations to operate, so butterfly valves are more suitable for frequent use.

Versatility:Gate valve: small resistance, good sealing, but not conducive to flow regulation, often used for dry pipe shutoff.Butterfly valve: small size, combined with the advantages of stop valve and ball valve, with good flow regulation performance, suitable for quick cut-off or flow regulation occasions, wide range of applications.

Space requirements: Butterfly valve has a simple structure, light and compact, occupies less space than gate valve, and has more advantages in fluid systems with limited space.

Maintenance: Butterfly valve has a simple structure, few parts, and easy maintenance; gate valve has a complex internal structure, multiple sealing mechanisms, and laborious maintenance