PRODUCT DETAILS

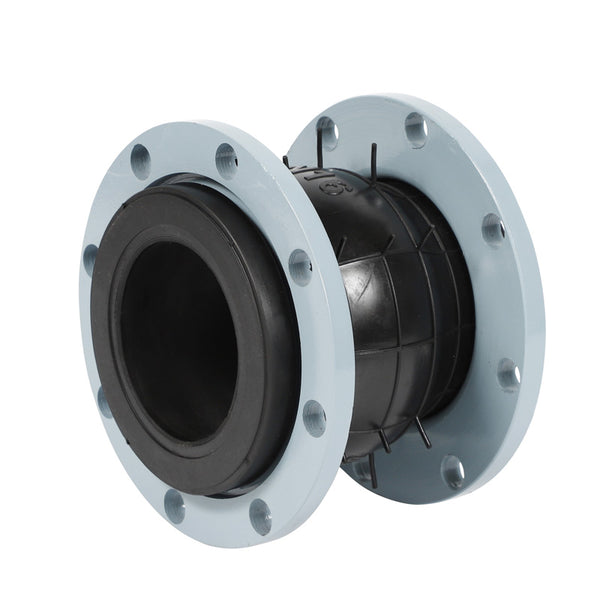

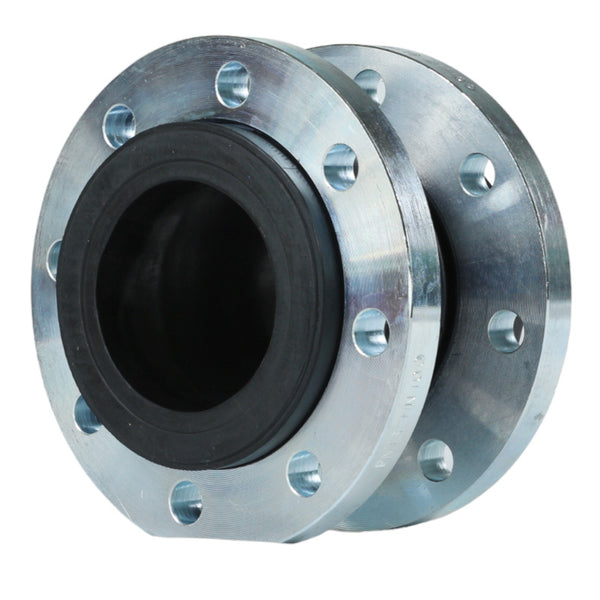

Single Sphere Connector With Flange Introduction

Rubber expansion joint is a common pipe connector, also known as rubber soft connection, which is mainly composed of rubber and steel wire. The main role is to connect the pipeline, play the role of connection, shock absorption, noise reduction and so on. It can withstand a certain pressure and displacement in the pipeline connection, so as to ensure the normal operation of the pipeline. Compared with traditional metal pipe fittings, it has better elasticity and flexibility, which can adapt to the deformation and vibration of the pipeline and reduce the stress concentration of the pipeline, thus prolonging the service life of the pipeline. It has good pressure resistance, corrosion resistance, abrasion resistance, oil resistance and other characteristics, and is widely used in construction, chemical industry, water conservancy, electric power, petroleum and other fields.

This Single Sphere Connector With Flange is designed to provide a flexible connection between pipes or equipment. The flange feature ensures a secure fit, reducing the risk of leaks or displacement. Its single sphere design allows for a high degree of movement, making it ideal for applications where movement is a concern.

Single Sphere Connector With Flange Drawing

Standard of Implementation

| Category | Details |

|---|---|

| Type | Flange |

| Face to Face | API609, BS5155, DIN3202, ISO5752 |

| Flange | DIN, BS, UNI, ISO, ANSI, AS, JIS |

| Mounting Flange | ISO5211 |

| Working Pressure | PN16 (200PSI) |

| Application | HVAC, Water Supply & Sewage, Food & Beverage, Chemical/Petrochemical Processing, Power and Utilities, Paper and Pulp, Ship Building |

Standard Materials Of Main Parts

| NO | PART NAME | MATERIAL |

|---|---|---|

| 1 | Sphere | EPDM/NBR |

| 2 | Flange | CS Coated With Zinc |

Dimensions:(mm)

| SIZE | L | Pn16 | Pn10 | ANSI150 | |||||||

| in | DN | D | D1 | n-d1 | D | D1 | n-d1 | D | D1 | n-d1 | |

| 1.25 | 32 | 95 | 140 | 100 | 4-18 | 140 | 100 | 4-18 | 117 | 89 | 4-16 |

| 1.5 | 40 | 95 | 150 | 110 | 4-18 | 150 | 110 | 4-18 | 127 | 98.5 | 4-16 |

| 2 | 50 | 105 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 152 | 120.5 | 4-19 |

| 2.5 | 65 | 115 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 178 | 139.5 | 4-19 |

| 3 | 80 | 135 | 200 | 160 | 8-18 | 200 | 160 | 8-18 | 191 | 152.5 | 4-19 |

| 4 | 100 | 150 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 229 | 190.5 | 8-19 |

| 5 | 125 | 165 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 254 | 216 | 8-22 |

| 6 | 150 | 180 | 285 | 240 | 8-23 | 285 | 240 | 8-23 | 279 | 241.5 | 8-22 |

| 8 | 200 | 210 | 340 | 295 | 12-23 | 340 | 295 | 8-23 | 343 | 298.5 | 8-22 |

| 10 | 250 | 230 | 405 | 355 | 12-17 | 395 | 350 | 12-23 | 406 | 362 | 12-25 |

| 12 | 300 | 255 | 460 | 410 | 12-17 | 445 | 400 | 12-23 | 483 | 432 | 12-25 |

| 14 | 350 | 255 | 520 | 470 | 16-27 | 505 | 460 | 16-23 | 533 | 476 | 12-29 |

| 16 | 400 | 255 | 580 | 525 | 16-30 | 565 | 515 | 16-27 | 597 | 539.5 | 16-29 |

| 18 | 450 | 255 | 640 | 585 | 20-30 | 615 | 565 | 20-27 | 635 | 578 | 16-35 |

| 20 | 500 | 255 | 715 | 650 | 20-33 | 670 | 620 | 20-27 | 699 | 635 | 20-32 |

| 24 | 600 | 260 | 840 | 770 | 20-36 | 780 | 725 | 20-30 | 813 | 749.5 | 20-35 |

REVIEWS

Download

FAQs

What is a rubber expansion joint?

A rubber expansion joint is a flexible connector made of rubber that is used to absorb movement, vibration, and thermal expansion in piping systems.

What are the main applications of rubber expansion joints?

They are commonly used in HVAC systems, water and wastewater treatment plants, chemical processing, power generation, and industrial piping systems.

What are the benefits of using rubber expansion joints?

They provide flexibility, reduce noise and vibration, compensate for misalignment, absorb thermal expansion, and protect equipment from stress and wear.

How to use a rubber expansion joint

When installing a rubber expansion joint, you need to select the right joint for your system, make sure the pipes are clean and aligned, and connect them between flanges. Tighten the bolts evenly in a star pattern, ensure proper movement allowance, check for stress and leaks, and perform regular maintenance inspections.