Obtained Certification

our unwavering dedication to quality is evident.

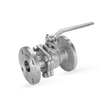

Precision Valve Manufacturing Excellence

We strive for excellence in valve products.

Quality Testing Equipment

Introducing Our New CNC Lathe and Driling Machines for Superior Butterly Valve Machining

Butterfly Valve Gate Valve Testing

Torque and Life Testing for Butterfly Valve and Gate Valves

Valve Life Test Bench

Provides detailed insights into valve pressure testing and other critical parameters.

Quality Testing Equipment

Sophisticated inspection and testing equipment is essential to ensure product reliability and safety.

Professional Inspectors

We have a team of expert inspectors dedicated to ensuring the safety and reliability of our products.

Ductile-lron-Grinding

Metallographic-microscope-observation

Spherical-content-observation

Shaft-hardness-test

Observe-the-dent

Record-position

Ultrasonic-testing

Magnetic-particle-testing

Penetration-detection

FAQs

Why do valve ductile iron parts need grinding?

Because it ensures precise dimensions, smooth surface finishes, and improved material properties. Cast parts often require grinding to meet tight tolerances, remove surface imperfections, and prepare for coatings or assembly.

What is valve metallographic microscope observation?

Valve metallographic inspection uses a microscope to analyze the microstructure of metals, evaluating features like structure, spheroidization rate, pearlite, ferrite, roughness, and finish to assess material quality and performance.

What is valve spherical content observation?

Spherical content observation analyzes the shape, size, and distribution of spherical features, like graphite nodules in ductile iron, to evaluate material properties such as strength, ductility, and quality.

What is Hardness Testing for Valves?

Hardness testing measures a material's resistance to deformation, reflecting valve quality and manufacturing. It helps detect defects like inclusions or porosity and ensures uniformity and performance.

What does valve observe the dent mean?

"Observe the dent" refers to examining a dent on a material's surface to assess its depth, size, and impact on structural integrity or performance. This is often used to evaluate damage or deformation caused by external forces.

What is ultrasonic testing for valves?

Ultrasonic testing uses waves to detect valve leaks. Turbulence from leaks generates ultrasonic signals, which sensors capture and analyze to pinpoint their location.

What is magnetic particle testing for valves?

Detects surface and near-surface defects in valves by applying a magnetic field. Defects create leakage fields that attract magnetic particles, forming visible indications of the flaws.

What is penetration detection for valves?

Penetration detection is a non-destructive testing method used to find surface-opening defects in metal or non-metal components. A special penetrant is applied to the surface, and a developer draws the penetrant from defects to reveal their presence.

What is a valve spectrometer?

A valve spectrometer is a high-precision analytical instrument used to analyze valve materials. Using spectroscopy, it accurately detects elements and their concentrations to ensure the valve's quality and performance.

Main Products

Standard valves for your choice