PRODUCT DETAILS

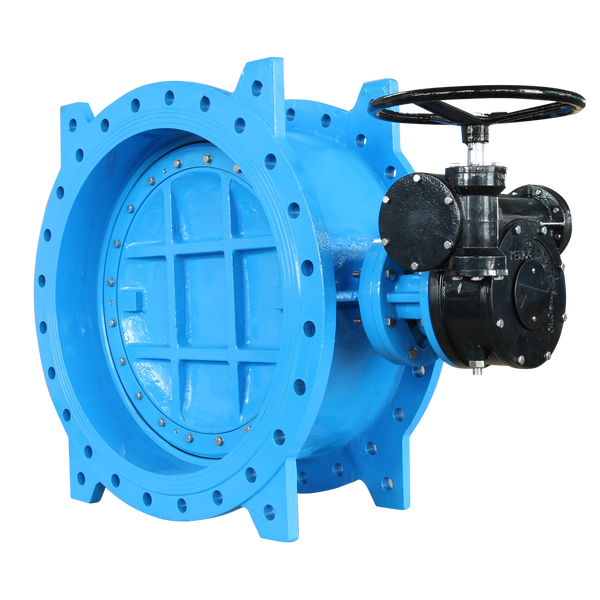

Double Eccentric Flanged Butterfly Valve Introduction

Double Eccentric Butterfly Valve is further improved on the basis of Single Eccentric Butterfly Valve. Its unique structural feature is that the axis of the valve stem not only deviates from the center of the butterfly plate, but also deviates from the center of the valve body. This double eccentric design allows the butterfly plate to quickly disengage from the valve seat when the valve opens, significantly reducing unnecessary excessive compression and friction between the butterfly plate and the valve seat. This improvement significantly reduces resistance to opening, reduces wear and significantly increases seat life. Due to the significant reduction in friction, the Double Eccentric Butterfly Valve can also be equipped with metal seats for enhanced performance and durability in high temperature applications.

Main features of double eccentric butterfly valve:

- Reasonable design, compact structure, easy to install and disassemble, easy maintenance.

- Eccentric structure reduces the friction of sealing ring and prolongs the service life of the valve.

- Completely sealed, zero leakage. Can be used in ultra-high vacuum conditions

- Replacement of the valve plate sealing ring, butterfly plate, shaft and other materials, can be applied to a variety of media and different temperatures.

The Double Eccentric Butterfly Valve is a marvel of engineering precision and a testament to advanced innovations in fluid dynamics. With its uniquely designed eccentric stem axis, the valve effortlessly breaks the mold, revolutionizing the way we control flow with functionality and breathtaking elegance. During operation, the disc disengages gracefully with minimal contact with the valve seat, which not only reduces wear and tear, but also ensures product longevity and reliability. This clever double eccentric configuration greatly reduces operating torque, ensuring smoother, more energy-efficient performance. In addition, the reduction in friction allows for the integration of a robust metal seat, thus extending the valve's field of application to high-temperature applications and providing peace of mind even in the most demanding environments. The Double Eccentric Butterfly Valve realizes the harmony of cutting-edge technology and durability, and is designed to not only meet but exceed the expectations of modern industrial needs.

Double Eccentric Flanged Butterfly Valve Drawing

Implementation Of Standards

| Category | Details |

|---|---|

| Type | Flange |

| Face to Face | API609, BS5155, DIN3202, ISO5752 |

| Flange | DIN, BS, UNI, ISO, ANSI, AS, JIS |

| Mounting Flange | ISO5211 |

| Working Pressure | PN16 (200PSI) |

| Application | HVAC, Water Supply&Sewage, Food&Beverage, Chemical/Petrochemical/Processing, Power and Utilities, Paper and Pulp, Ship Building |

Standard Materials Of Main Parts

| ITEM | PART NAME | MATERIAL |

|---|---|---|

| 1 | Bushing | BRONZE/EPDM |

| 2 | Bottom Shaft | SS420 |

| 3 | Body | GGG50 |

| 4 | Packing | EPDM |

| 5 | Retainer | CS EPOXY COATED |

| 6 | Taper Pin | SS416 |

| 7 | Disc | GGG50 |

| 8 | Disc Sealing | EPDM |

| 9 | Stuffing Flange | GGG50 |

| 10 | Support | CS |

| 11 | Top Shaft | SS420 |

| 12 | Cover | GGG50 |

| 13 | All Fasteners | A2-70 |

Dimensions:(mm)